Adhesives

Comments Off on AdhesivesAdhesives create a strong bond between two or more surfaces, allowing them to stick together. Generally, they function through a combination of physical and chemical mechanisms. In many cases, these substances fill in the tiny irregularities present in the material exteriors. Meanwhile, some are intended to chemically react with the surfaces with which they come into touch.

This article will explore the basics of adhesive substances, encompassing their various types and essential considerations when choosing the most suitable kind.

Types of Adhesives

Different adhesive substances are available, each intended for specific applications and materials. The selection process usually considers the materials to be bonded, the bond strength, environmental conditions, and the preferred curing method. Below are some of the commonly used and popular types:

Acrylic

Acrylics cure relatively quickly at room temperature, allowing for efficient production and assembly processes. This makes them suitable for both porous and non-porous surfaces. They also offer good resistance to many chemicals, oils, and solvents.

Cyanoacrylate (Super Glue)

Super glue is a fast-acting material that joins when it comes into contact with surface moisture. It is excellent for bonding small parts, plastic, rubber, metal, and non-porous materials. Although super glue may make strong, clean connections, it may not work well under heavy loads or extreme temperatures.

Epoxy

Epoxy is well-known for its adaptability and high-performance bonding properties. It is made up of two main components: resin and hardener. When these are combined in the proper ratio, a chemical reaction occurs. This results in the development of a strong and long-lasting bond.

Polyurethane (PU)

PU adhesives offer excellent flexibility and elongation properties. This allows them to endure movements and vibrations without losing integrity, making them ideal for applications requiring flexibility. They provide strong bonds on various materials, including metals, plastics, wood, concrete, and composites.

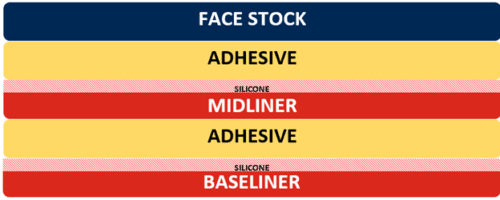

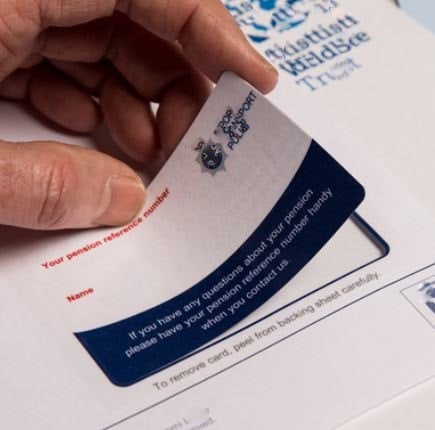

Pressure-Sensitive

Pressure-sensitive adhesives (PSAs) adhere when light pressure is applied and are commonly used in tapes, labels, and sticky notes. They also provide instant bonding and are easy to use without heat, water, or solvents.

Silicone

Silicone sealants have exceptional electrical insulating properties and are highly resistant to water and moisture. They are widely used in the construction industry for sealing gaps and joints in windows, doors, and other building components. They are also utilized in weatherproofing applications.

Factors To Consider During Adhesive Selection

Selecting the right adhesive for a particular application ensures a strong and durable bond. The following are several factors should be carefully considered during the selection process:

Substrate Materials

Understanding the composition and surface characteristics of the materials to be bonded is critical. For instance, porous materials have small pores that absorb liquids or gases. Hence, the sealant must be able to penetrate these voids and create a strong bond within the substrate. Conversely, it must bond through mechanical or chemical interlocking for non-porous materials.

Bond Strength Requirements

Different applications demand varying levels of bond strength to ensure the reliability and longevity of the bonded assembly. High-strength sealants are needed in the construction, aerospace, and automotive industries to provide exceptional force for significant loads and stresses. Meanwhile, certain applications involve materials that experience frequent movement or vibration. For such situations, more flexible bonds are necessary to accommodate these forces without causing the assembly to break.

Environmental Conditions

Environmental factors can significantly impact the adhesive’s properties, longevity, and effectiveness. For example, some substances may lose flexibility in high-temperature environments, while others may become brittle in low-temperature conditions. In addition, moisture-sensitive sealants may experience reduced bond strength or slow curing when exposed to high humidity.

Curing Time and Process

The curing time is the duration required for the adhesive to reach its full strength and develop a robust bond. Rapid-curing substances offer shorter assembly times as they achieve sufficient force quickly. On the other hand, the curing process refers to the chemical or physical changes that occur after the sealant is applied.

Other factors to consider during the selection process include the following:

- Application method

- Service life and longevity

- Ease of use

- Cost

Strata-Tac for High-Quality Adhesive Coating Services

At Strata-Tac, we take pride in our advanced capabilities to produce various adhesive coatings, ensuring our customers receive high-quality services. Our state-of-the-art facility has multiple coating lines and methods, enabling us to precisely and efficiently cater to different application needs. We boast two cutting-edge 61-inch reverse and offset gravure coating lines and a 40-inch UV coating line.

Contact us or request a quote to get started!