What is a Piggyback Label?

Comments Off on What is a Piggyback Label?Piggyback labels are widely used for a variety of applications. Below, we will go in depth on their construction, applications, and a few examples of the types of piggyback labels available.

Construction

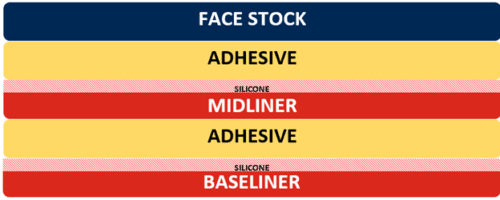

Piggyback labels are effectively two labels combined into a single construction. As illustrated in the figure below, a piggyback label consists of a face stock on top of two release liners. The liner in the middle is often referred to as the “midliner”. The liner at the bottom is referred to as the “baseliner”. Depending on the application, the midliner and liner may be film or paper. The adhesives may also differ. A common version of this is a permanent adhesive on the bottom and a removable adhesive on the facestock.

Applications

Piggyback labels are widely used in the logistics industry, where piggyback labels enable easy and accurate asset tracing. They are also used in the in promotional and marketing applications in the form of coupons and direct mail campaigns. In healthcare and similar markets, piggyback labels are used for regulatory purposes where chain-of-custody is paramount.

Piggyback Examples

Here are some examples of Strata-Tac’s piggyback constructions. For more information on a specific product, click on the product code to view the online spec sheet.

- PBIJF088: 3.5 Mil Matte Inkjet Paper Piggyback with Permanent Adhesive & 1.5 Mil Polyester (PET) MidLiner

- PBWX051: 2 Mil Matte Laser White Polyester (PET) Piggyback with Permanent Adhesive

- PBGLR051: 2 Mil Gloss Laser Clear Polyester (PET) Piggyback with Ultra-Removable Adhesive

- PBLXQHI083: 60# Latex Piggyback with Blood Bag Adhesive & Imaging MidLiner

Click here to view more of our piggyback constructions.

Piggy “Half-Back”

A piggy half-back, or an incomplete piggyback product. It only consists of the midliner & baseliner with the adhesive between the two. The face stock and adhesive do not (yet) exist on a half back. Label converters can apply a label stock of their choosing to complete the piggyback construction, giving the converter the ability to offer more piggyback options to their customers. Piggybacks can have a film midliner, such as OLSI037, or a paper midliner like PHB143.

Custom Piggybacks

Strata-Tac offers custom piggyback label stocks. This can include using specific topcoats, face stocks, adhesives, liners, and even custom adhesive patterns to fit your application. If you would like to discuss a specific application, please fill our our custom product builder, or call us at 630-879-9388.